DC 30mm Aluminum Front Bend Centrifugal Fan for Air Curtain

Overview Product Description Slim Installation Height and High Air Flow Rate with lowest Noise PBM tangential blowers co

Overview

Basic Info.

| Model NO. | PC3N30B24T |

| Sound Level | 40dB(a) |

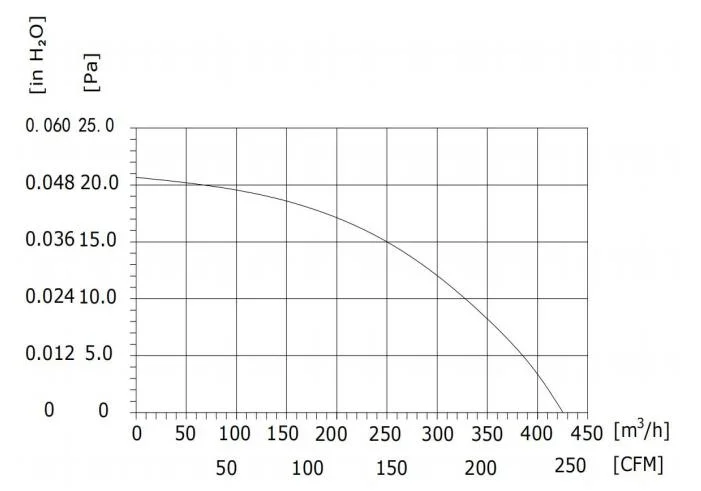

| Air Pressure | 21PA |

| Rated Voltage | 24V |

| Rated Power | 4.8W |

| Rated Speed | 2550rpm |

| Transport Package | Standard Exporting Package |

| Specification | BE37.5DC |

| Trademark | PBM |

| Origin | China |

| HS Code | 8414519900 |

| Production Capacity | 50, 000PCS/Year |

Product Description

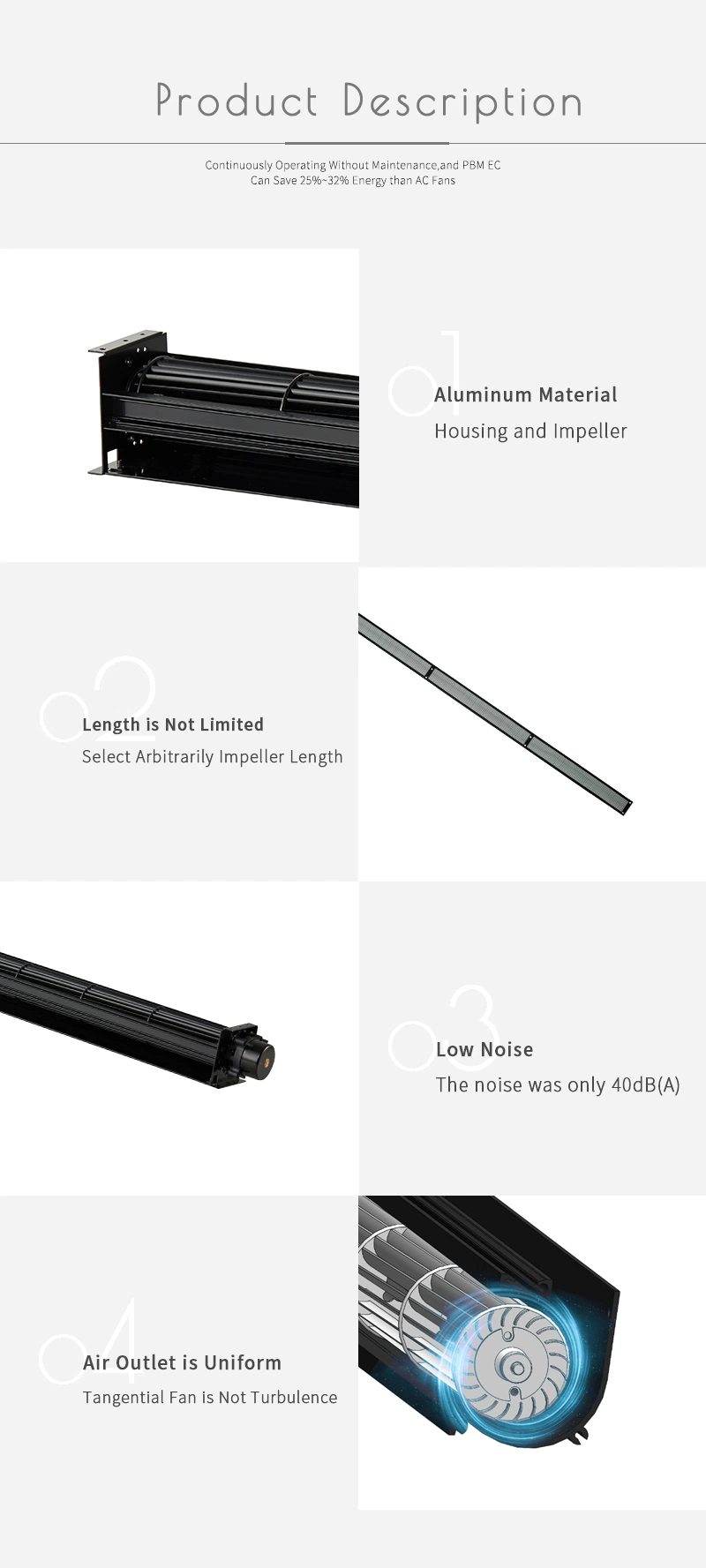

Product Description

Slim Installation Height and High Air Flow Rate with lowest Noise

Impeller Sizes: from 30mm to 80mm diameter;Sound Level: from 32dBA to maximum 48dBA according different rotation speed;Airflow: maximum to 600CMH, Cubic Meter per Hour, equal to approx. 353CFM , Cubic Feet per Minute;Air Pressure: Maxim to 80Pa, equal to 8.16mm H2O and to 0.32 inches H2O;Power: Maximum motor input power goes to 100W motor diameter 80mm.

Product Parameters

General Characters:

| 1-1 | Rated Voltage | 24 VDC |

| 1-2 | Operating Voltage | 16~28 VDC |

| 1-3 | Low-Start Voltage | 15 VDC |

| 1-4 | Rated Speed | 2550RPM |

| 1-5 | Input Current | 0.2A |

| 1-6 | Input Power | 4.8W |

| 1-7 | Acoustical Noise | 40dB(A) |

| 1-8 | Life Expectance | 50,000Hours(L10) At 40ºC room, humidity 15%~65%RH |

| 1-9 | Direction of Rotation | Anti-clockwisesee on motor |

| 1-10 | Direction of Air Flow | All round |

| 1-11 | Insulation Class | Class B |

| 1-12 | Insulation Resistance | 50Mega Ohm minimum at 500VDCBetween frame and (+) terminal |

| 1-13 | Motor Protection | Locked rotor protectionPolarity protectionAutomatic restart capability |

| 1-14 | Speed Control | Control input 0~10VDC |

| 1-15 | Dielectric Strength | 5mA maximum at 500VAC 50Hz five secondBetween frame and (+) terminal |

| 1-16 | Signal Output | No |

Mechanical Characters:

| 2-1 | Dimension | 48mm X 50mm X 705mm (see dimension drawing) |

| 2-2 | Material of Impeller | Steel |

| 2-3 | Number of Blades | 22 |

| 2-4 | Impeller Plate | Injection-moulded round sheet-metal plate |

| 2-5 | Mounting position | Any |

| 2-6 | Surface of Rotor | Electrophoresis |

| 2-7 | Bearing System | NMB ball bearing |

| 2-8 | Lead Wire | Red , Black, White AWG22# |

| 2-9 | Weight | 837g |

| 2-10 | Package | Standard |

Electrical Protection:

| 3-1 | Locked-rotor Protection | Over-current limiting circuit protects motor from damage at least for 72 hours of locked rotor condition at rated voltage. |

| 3-2 | Maximum Current under Locked Rotor | A, Typical inrush current when the motor is trying to re-start under locked rotor conditions is 2~4 times the normal running current reoccurring and for 16~20% of restarting cycle period. B, If he CL function is used this restarting inrush current is about the same as the normal running current. |

| 3-3 | Reverse Polarity Protection | No damage if the positive and negative leads are reversed under maximum operation voltage conditions. |

| 3-4 | Over Voltage Protection | The circuit will be shut down automatically when input voltage over 30VDC. And re-started when Voltage down to 30VDC below. |

| 3-5 | Soft Start | In 5 seconds after power on and speed control voltage gets to 1.5V. |

Enviromental Characters:

| 4-1 | Operating Temperature | -25ºC to 60ºC |

| 4-2 | Storage Temperature | -40ºC to 75ºC |

| 4-3 | Operating Humidity | 5% to 90% RH |

| 4-4 | Storage Humidity | 5% to 95% RH |

| 4-5 | Drop Test | In minimum packaging condition fan withstand each one drop of three faces from 30cm distance height onto 10mm thickness of wooden board |

| 4-6 | Vibration Test | Sine Wave. Displacement amplitude: 0.75mm (Equivalent 10G). Frequency Range: 10Hz~55Hz / 30 sec. 55Hz~10Hz / 30 sec Linear Scanning 120 Cycle Endurance timer per axis: 2 Hours Orientation: X,Y,Z. |

| 4-7 | Shock Test | Apply peak acceleration 50g and keep duration of the pulses for 11ms (Half sine wave). |

| 4-8 | All the material meets RoHS standard. |

Detailed Photos

Company Profile

FAQ

Send to us